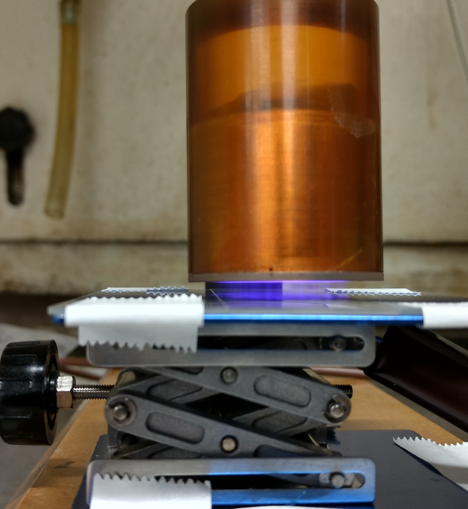

We worked on exploring the potential of ACP technology for microbial pathogens such as Listeria and Salmonella in high- and low-moisture food products. One of the key advantages of this technology is that plasma can be created inside sealed packages with trapped reactive species. This is an advantage for food processors, as it eliminates cross-contamination. My lab recently explored the application of in-package ACP technology for high-moisture products such as ham and low-moisture products such as freeze-dried pet foods. The modified atmosphere containing 20% O2 + 40% N2 + 40% CO2 was effective in inactivating the Listeria when plasma was produced inside the package (top cited article in Journal of Food Science). Our research helps to optimize the process and storage conditions for in-package ACP treatment to reduce Listeria monocytogenes, while maintaining the quality of ham. Since there are several recalls of ready-to-eat meat products, this work has huge importance in the industrial sector and our research will help future development of in-package cold plasma technology to reduce these outbreaks and recalls.

Manuscripts:

- *Yadav, B., & **Roopesh, M. S. In-Package atmospheric cold plasma treatments of freeze-dried pet foods: Effect of treatment time, water activity, and storage on the inactivation of Salmonella. Innovative Food Science and Emerging Technologies. More information

- *Yadav, B., *Spinelli, A. C., Govindan, B., Misra, N. N., Tsui, Y. Y., McMullen, L. M., **Roopesh, M. S. Effect of in-package atmospheric cold plasma discharge on microbial safety and quality of ready-to-eat ham in modified atmospheric packaging during storage. Journal of Food Science (Available online). More information

- *Feizollahi, E., Misra, N. N., **Roopesh, M. S. Factors influencing the antimicrobial efficacy of dielectric barrier discharge (DBD) atmospheric cold plasma (ACP) in food processing applications. Critical Reviews in Food Science and Nutrition. More information

Funding support: