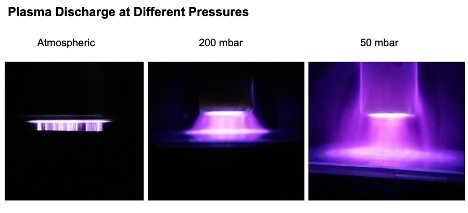

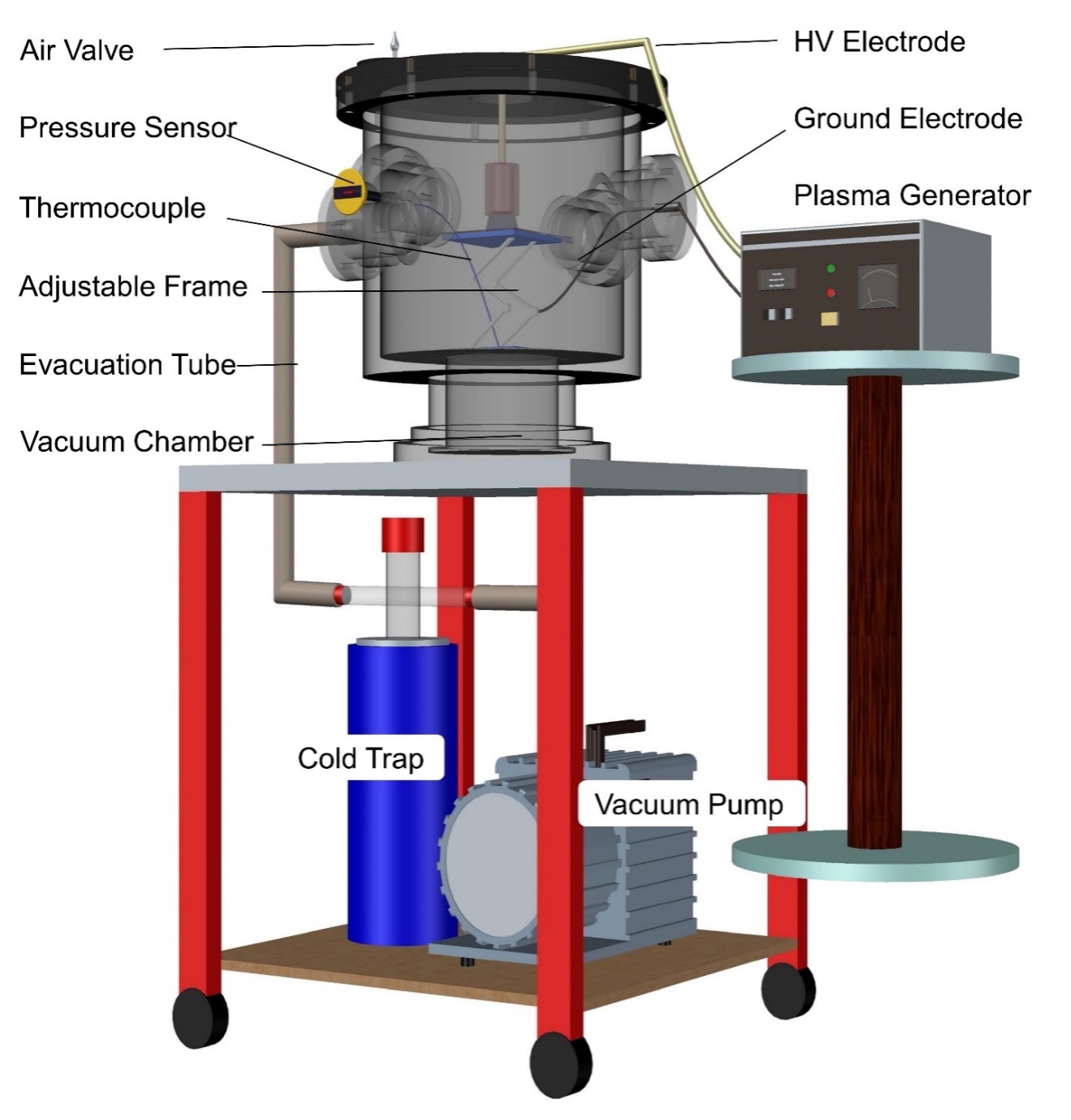

Our research team recently developed several novel ways to integrate cold plasma technology in a conventional food processing line. A novel low-pressure plasma cooling process was developed to achieve simultaneous fast cooling and elimination of microbial pathogens in agricultural materials and food products in a single process. We analyzed the influence of process parameters including treatment time, pressure, and post-treatment storage, on the inactivation of Salmonella Typhimurium in fresh-cut apples. In addition, cut apples dipped in citric acid followed by PiLPC increased the inactivation of Salmonella and polyphenol oxidase, the key enzyme involved in enzymatic browning reactions in cut apples. This innovative process technology can improve the shelf life of a wide variety of products including fresh produce and meat products, while reducing microbial contamination in them in the future.

Manuscripts:

- *Adam, A. M., *Yadav, B., *Prasad, A., *Gautam, B., Tsui, Y., & **Roopesh. M. S. Salmonella inactivation and rapid cooling of fresh cut apples by plasma integrated low-pressure cooling. Food Research International. More information

- *Adam, A. M., Jeganathan, B., Vasanthan, T., & **Roopesh. M. S. Dipping fresh-cut apples in citric acid before plasma integrated low-pressure cooling improves the inactivation of Salmonella and polyphenol oxidase. Journal of the Science of Food and Agriculture. More information

Funding support: