Process Engineering Research to Improve Safety, Quality, & Utilization of Water, Food, & Environment

The Food Safety and Sustainability Engineering (FSSE) Research lab at the University of Alberta focuses on improving the safety, quality, and utilization of water, food, and the environment. We are working towards utilizing conventional technologies and developing advanced technologies to improve food safety and overall water, food, and environmental sustainability.

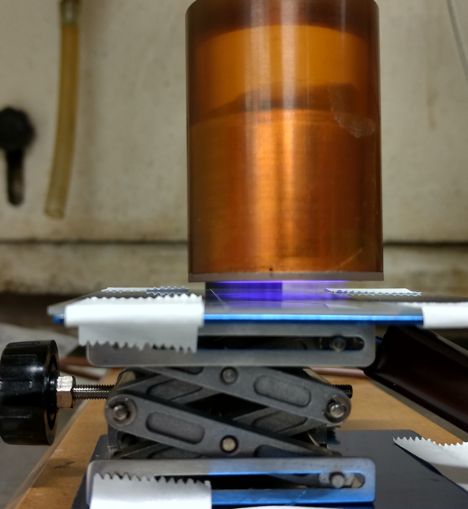

- Atmospheric cold plasma and plasma-activated water

- Ultrafine (nano/micro) bubble technologies

- Ultraviolet light emitted from the LED

- 3D printing/additive manufacturing of food/biomaterials

The following are the key research areas:

- Sanitation, Disinfection & Cleaning in the Food Processing Industry

- Conventional antimicrobial interventions (e.g., ozone, peracetic acid, lactic acid, citric acid, hydrogen peroxide, dry heat, quats)

- Cold plasma, ozone, and UV-based hybrid treatment development with conventional antimicrobial interventions

- Agri-Food Processing & Engineering

- Low-moisture food safety engineering

- 3D printability of gels prepared from plant proteins, carbohydrates, and fibers, as well as functionality improvement (e.g., peas, canola, lentil, faba bean, etc.)

- Conventional agri-food process intensification and development of novel processes

- Antimicrobial Applications of Atmospheric Cold Plasma

- Plasma-activated air, water, micro/ultra fine (nano) bubbles, and mist

- Microbial decontamination

- Inactivation of microbial biofilms in the processing environment

- Ultrafine (Nano/Micro) Bubble Technologies

- Microbial biofilm inactivation

- Water treatment

- UV LED applications

- Microbial decontamination

- Water treatment

- Agricultural and Environmental Applications of Atmospheric Cold Plasma

- Seed decontamination and germination improvement

- Mycotoxin degradation

- Plasma-activated water as a green fertilizer and sanitizer for greenhouse and indoor farming - hydroponics and aquaponics

- Wastewater Treatment

- Atmospheric cold plasma bubble technology development

- Ozone and Ultraviolet light pulses emitted from LEDs

- Microbial decontamination

- Degradation of organic and inorganic contaminants in wastewater

Principal Investigator

Dr. Roopesh Mohandas Syamaladevi (M. S. Roopesh)

Associate Professor

Food Safety & Sustainability Engineering

Department of Agricultural, Food & Nutritional Science

Faculty of Agricultural, Life & Environmental Sciences

Offices: 3-16 Agriculture/Forestry Centre &

1-045 Agri-Food Discovery Place

Phone: 780-492-8413

Fax: 780-492-4265

Email: roopeshms@ualberta.ca

Office Hours: By appointment

Address:

University of Alberta

3-16 Agriculture/Forestry Centre

Edmonton, AB

Canada T6G 2P5

FSSE Laboratory:

2-49 Agriculture/Forestry Centre

Plasma-activated nanobubble water technology

Our lab developed the method and a reactor to generate plasma-activated nanobubble water (PANBW). Several applications of PANBW are in the pipeline, including wastewater treatment, biofilm inactivation, green fertilizer production etc. The PANBW was produced by injecting plasma species into nanobubble water (NBW). The size and concentration of the nanobubbles present in PANBW were comparable to NBW, but with enhanced antibiofilm properties. The state-of-the-art nanoparticle tracking analysis showed that PANBW were stable for a long time with not much change in the size, concentration, Read more

Novel technologies to improve meat safety and quality

Escherichia coli can exist as biofilms on equipment or contact surfaces used in the meat packing industry and can contaminate the beef products. Conventional methods such as the application of chemical disinfectants are not always effective in removing biofilms and they are not environmentally friendly either. Hence there is a need to explore the efficacy of new technologies to reduce E. coli biofilms in meat packing facilities. As part of the project funded by the Beef Cattle Research Council (BCRC) and Agriculture and Agri-Food Canada, and Results Driven Agriculture Research (RDAR), we are exploring the inactivation efficacies.... Read more

The agricultural and food processing industries produce large amounts of wastewater. The wastewater from these industries contains large quantities of organic and inorganic pollutants, and pathogenic microorganisms, so safe disposal requires adequate treatment, otherwise causing public health issues.

In addition, water quality and hygiene of drinking water systems (DWS) are extremely important in broiler and livestock production. Drinking water is susceptible to microbial contamination and DWS are prone to biofilm build-up over time. Biofilms are complex communities of microorganisms, surrounded by extracellular polymeric substances attached to surfaces. Microbial...Read more

Mycotoxin degradation in cereal grains by cold plasma technology

Mycotoxins directly affect the health of human beings and animals, along with causing a huge economic loss to food/feed industries. It is estimated that 25% of agricultural commodities are contaminated with mycotoxins every year. There is no effective method currently available to eliminate the occurrence of mycotoxins in cereal grains and their products. Our lab has been testing atmospheric cold plasma (ACP) technology for its ability to reduce the number of mycotoxins (e.g., deoxynivalenol, zearalenone, T2- and HT-2 mycotoxins) affecting the cereal grains and oilseeds grown in western Canada (e.g., wheat, barley, canola, oats etc.).... Read more

Plasma integrated low-pressure cooling (PiLPC)

Our research team recently developed several novel ways to integrate cold plasma technology in a conventional food processing line. A novel low-pressure plasma cooling process was developed to achieve simultaneous fast cooling and elimination of microbial pathogens in agricultural materials and food products in a single process. We analyzed the influence of process parameters including treatment time, pressure, and post-treatment storage, on the inactivation of Salmonella Typhimurium in fresh-cut apples. In addition, cut apples dipped in citric acid followed by PiLPC increased the inactivation of Salmonella and polyphenol oxidase.... Read more

Improvement in plant protein 3D printability and functionality

To address recent consumer interest in plant protein-based food products, we are working on the projects funded by Alberta Innovates and NSERC CREATE, that focuses on the utilization of Canadian protein crops. Specifically, we are using cold plasma technology to improve the functional properties i.e., gelling, digestibility, and solubility of various proteins, which led to a patent application. For the first time, we demonstrated the ability of cold plasma technology as a pre-treatment to prepare strong pea protein gels without using high temperatures. We expanded this work by using plasma activated water bubble (PAWB) technology to prepare pea protein gels.... Read more

Plasma activated water bubbles for barley steeping

Deoxynivalenol (DON) is an important mycotoxin, that can cause major economic loss to grain farmers and malting industry. DON can end up in final products if the malting barley is contaminated with DON. Barley grains free of DON are required for malting and the DON-infected barley is rejected at relatively low levels (0.5 up to 4 ppm). In our research, plasma activated water bubble (PAWB) technology was utilized for barley steeping to reduce DON and improve seed germination, which resulted in a patent application and a technology licensing opportunity at the University of Alberta. Currently, we are looking for industry partners for future scale-up of PAWB.... Read more

In-package cold plasma treatment

We worked on exploring the potential of ACP technology for microbial pathogens such as Listeria and Salmonella in high- and low-moisture food products. One of the key advantages of this technology is that plasma can be created inside sealed packages with trapped reactive species. This is an advantage for food processors, as it eliminates cross-contamination. My lab recently explored the application of in-package ACP technology for high-moisture products such as ham and low-moisture products such as freeze-dried pet foods. The modified atmosphere containing.... Read more

Biofilm inactivation inside pipelines by plasma activated water bubbles

Our recent study tested the continuous production and disinfection effectiveness of plasma activated water bubble (PAWB) under different hydrodynamic regimes (e.g., laminar, transitional and turbulent) against mixed species biofilms. We built a lab-scale drinking water system with microbial biofilms grown inside them. PAWB were generated and circulated continuously in the drinking water system. Increasing Reynold’s number of water circulation significantly resulted in the higher inactivation of the surface-attached cells into the.... Read more